Introduction

Selecting the right forklift can significantly boost your warehouse efficiency, safety, and overall productivity. With various models, fuel types, and features available, it’s easy to feel overwhelmed. In this guide, we’ll break down the key factors you should consider before making a forklift investment. By the end, you’ll be better equipped to choose a forklift that aligns with your unique operational requirements and long-term goals.

Assess Your Operational Requirements

Load Capacity and Weight Limits

Start by evaluating the typical loads you’ll be lifting. Different forklifts have varying load capacities, so it’s crucial to choose a model that can handle your heaviest items without straining. Consider not just current but also future needs—opting for a slightly higher capacity may save you from having to upgrade prematurely.

Lift Height and Warehouse Layout

The maximum lift height should match (or exceed) your warehouse’s tallest shelving units. Also, think about aisle widths and turning radiuses. If your facility features narrow aisles or tight corners, a forklift specifically designed for confined spaces may help you navigate efficiently without damaging inventory or infrastructure.

Indoor vs. Outdoor Use

Where you plan to operate the forklift matters. If most of your work takes place indoors, an electric model with low emissions and quieter operation might be best. For outdoor or rough terrain tasks, however, diesel or LPG-powered forklifts often deliver the necessary power and stability.

Usage Frequency

How often will your forklift be in use? If you’re running multiple shifts daily, choosing a durable, higher-end model could reduce wear and tear, minimizing long-term costs. Occasional use might warrant a more budget-friendly option.

Consider the Fuel Type and Power Source

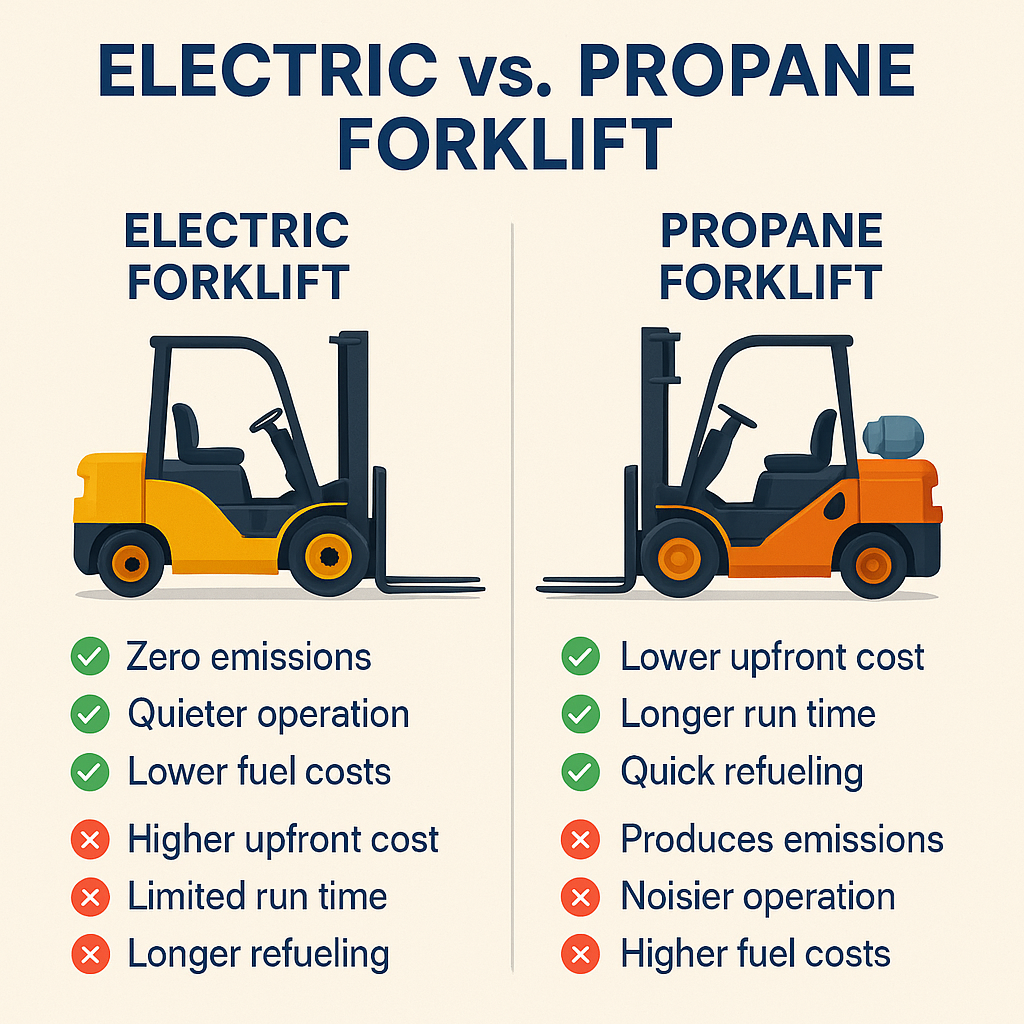

Electric Forklifts

Electric forklifts are ideal for indoor environments thanks to zero emissions, lower noise levels, and reduced maintenance needs. While the upfront cost can be higher, they often pay off in the long run, especially if you have access to efficient charging solutions.

Diesel and LPG Forklifts

If you need a machine that can handle heavy outdoor work or uneven ground, diesel or LPG forklifts may be the way to go. They generally offer higher torque and power but come with additional maintenance responsibilities and fuel costs.

Evaluate Maneuverability, Size, and Ergonomics

Maneuverability in Tight Spaces

For warehouses with narrow aisles, consider forklifts that feature a smaller footprint and excellent turning capabilities. Specialized designs, like narrow-aisle or reach forklifts, can help you maximize storage space and improve overall efficiency.

Operator Comfort and Safety Features

Look for ergonomic seating, intuitive controls, and good visibility from the operator’s position. Safety features—such as backup alarms, lights, and mirrors—can reduce the risk of accidents and injuries. A comfortable, confident operator is more productive and less prone to errors.

Factor In Budget and ROI

Initial Investment vs. Long-Term Savings

While it might be tempting to choose the cheapest option available, consider the long-term costs. Quality forklifts often yield higher returns by reducing downtime, maintenance costs, and operator fatigue. Assess the total cost of ownership rather than just the purchase price.

Financing and Leasing Options

If you’re not ready for a full cash purchase, explore financing or leasing arrangements. These options can help you preserve capital and maintain flexibility as your business needs evolve.

Conclusion: Get Expert Guidance

Choosing the perfect forklift involves balancing many factors—capacity, environment, fuel type, ergonomics, and budget. The right decision can lead to improved efficiency, reduced costs, and safer operations. If you need personalized advice, don’t hesitate to reach out to our team at Miramar Forklift. We’re here to help you identify the best solution for your unique needs.