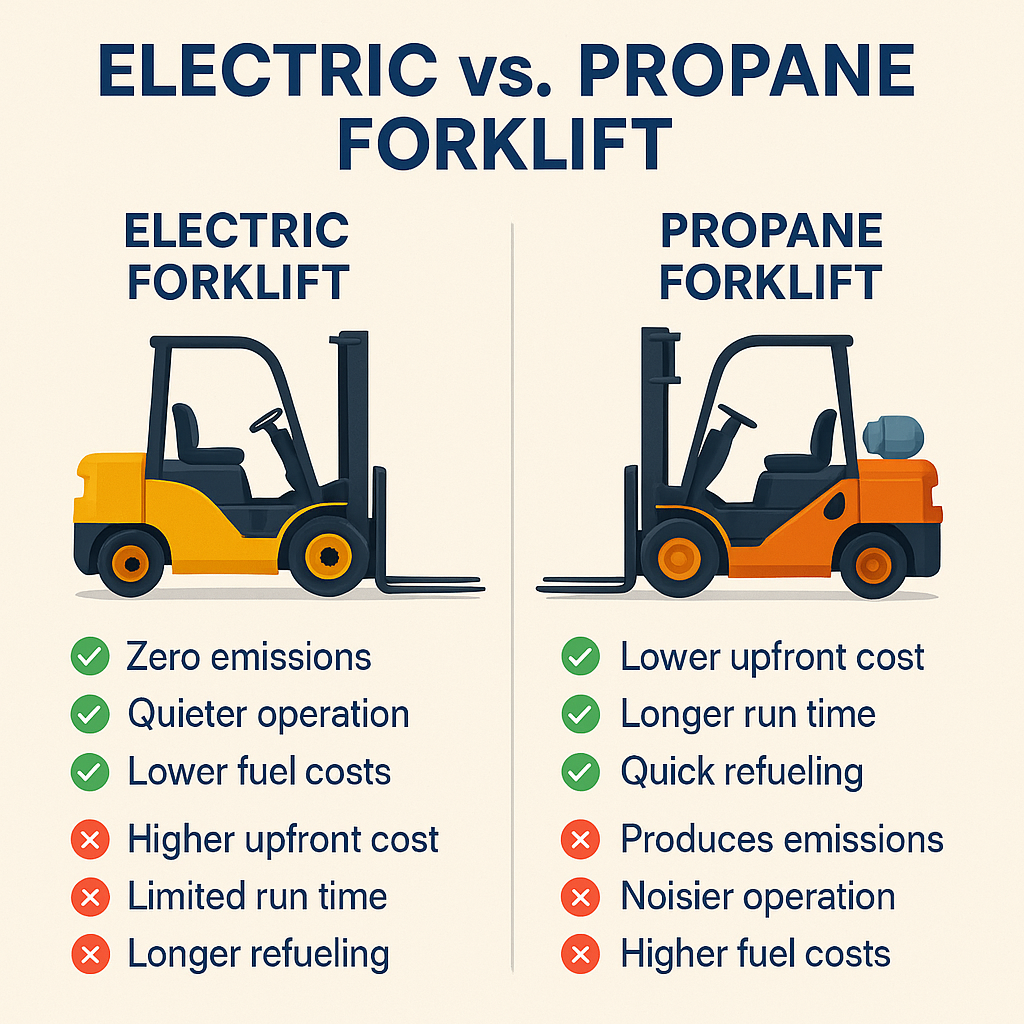

Because a broken-down forklift always costs more than a scheduled tune-up. Let’s be honest: forklift maintenance isn’t the most exciting part of your day—but it might be one of the most important. If you’re running a busy warehouse or job site, you already know how much a single downed forklift can slow everything (and everyone) down. So, how often should you service your forklift? The short answer: it depends on how you use it. But we’re not going to leave you hanging—this guide breaks it down in plain English. Why Regular Forklift Service Matters If you’ve ever searched for “forklift repair near me” in the middle of a shift, you know the stress. Regular maintenance helps avoid: Think of it this way: a little tune-up now can save you a lot of headaches (and invoices) later. The Basic Forklift Service Schedule Here’s a practical rule of thumb based on industry standards and what we see every day in the field: Type of Service Frequency Daily Checks Before each shift Minor Service Every 250 hours of operation Full Service Every 500 hours of operation Deep Inspection Annually (or every 2,000 hours of operation) Export to Sheets Pro Tip: Electric and propane forklifts have different service needs. If you’re running an electric unit, battery checks and charger inspections are key to keeping your electric forklift running smoothly. For propane forklifts, watch for fuel system wear and filter clogs – critical for preventing unexpected propane forklift repair. What’s Included in a Standard Forklift Maintenance Visit? When our certified technicians perform a forklift service, they’re not just kicking the tires. They’re running through a comprehensive forklift maintenance checklist that typically includes: It’s all about catching small issues before they become big, costly problems. Don’t Wait for a Breakdown: Partner with the Pros Ignoring your forklift maintenance schedule is like playing Russian roulette with your productivity. Whether you have one forklift or a whole fleet, proactive service is the smartest investment you can make. It extends the life of your equipment, keeps your operators safe, and ultimately saves you money. Ready to get your forklifts on a reliable service plan? Our team offers comprehensive forklift repair services and preventive maintenance programs designed to fit your specific needs and usage. Looking for “forklift service near me”? Give us a call today to schedule your next appointment or to learn more about our tailored maintenance plans. Let’s keep your operations moving! How Often Should Forklifts Be Serviced? A Real-World Guide for Warehouse Pros Because a broken-down forklift always costs more than a scheduled tune-up. Let’s be honest: forklift maintenance isn’t the most exciting part of your day—but it might be one of the most important. If you’re running a busy warehouse or job site, you already know how much a single downed forklift can slow everything (and everyone) down. It impacts your whole operation, from delivery schedules to operator morale. So, how often should you service your forklift? The short answer: it depends on how you use it. But we’re not going to leave you hanging—this guide breaks it down in plain English, giving you a solid forklift maintenance schedule to follow. Why Regular Forklift Service Matters If you’ve ever searched for “forklift repair near me” in the middle of a frantic shift, you know the stress. Regular maintenance helps avoid: Think of it this way: a little tune-up now can save you a lot of headaches (and invoices) later. It’s truly about forklift downtime prevention. The Basic Forklift Service Schedule Here’s a practical rule of thumb based on industry standards and what we see every day in the field. Remember, your forklift manufacturer’s recommendations in the operator’s manual are always your primary guide, but this is a solid starting point: Type of Service Frequency What’s Checked (Examples) Daily Operator Checks Before each shift Fluid levels, tire condition, horn, lights, brakes, forks, and overall visual inspection. (This is huge for forklift safety!) Minor Service / PM1 Every 250 hours of operation (approx. 1-2 months) Fluid top-offs, basic lubrication, brake inspection, checks on steering, lift chains, and minor adjustments. Full Service / PM2 Every 500 hours of operation (approx. 2-3 months) All PM1 items plus fluid changes (oil, hydraulic), filter replacements, more in-depth brake and hydraulic system checks. Major Service / PM3 Every 1,000 hours of operation (approx. 6 months) All PM2 items, plus spark plug replacement (for IC models), comprehensive system diagnostics, and major component inspections. Annual Deep Inspection Annually or every 2,000 hours (whichever comes first) A complete overhaul, including all previous services, detailed engine/motor inspection, transmission, drive axle, and mast inspection. This is where we catch bigger issues! Pro Tip: Electric forklift service and propane forklift repair have slightly different needs. For electric units, battery watering, terminal cleaning, and charger inspections are crucial. For propane forklifts, we’ll pay extra attention to the fuel system, hoses, and filter clogs. Understanding these nuances helps keep your specific lift truck running optimally. What Happens During a Forklift Maintenance Visit? When our certified forklift technicians come out for a scheduled service, they’re not just kicking tires. They’re performing a thorough inspection and addressing potential issues before they become major problems. Here’s a general idea of what a comprehensive forklift service company like ours will cover: Don’t Wait for a Breakdown Ultimately, the best time to get your forklift maintenance done is before you need an emergency repair. Consistent, planned service not only extends the life of your equipment but also boosts productivity and ensures the safety of your operators. Whether you have a single used forklift or a whole fleet, setting up a regular maintenance schedule with a trusted forklift service company is the smartest decision for your business. We offer forklift repair services for all major brands, both on-site and in our shop.